Reliable Commercial Epoxy Flooring Perth

Contact us today to find out more about our solutions.

Request a Free Consultation

Our Trusted Clients

Top Quality Commercial Epoxy Flooring

Commercial spaces are where epoxy flooring established itself as a leading substrate and with great reason. When it comes to durability, longevity, and design, no material does it better than commercial epoxy flooring.

Kitchens, warehouses, factories, hospitals, and showrooms – just to name a few – require hard-wearing surfaces and equipment that are also easy to clean. The same goes for their floor. Spills, drops, and foot traffic are plentiful in public and industrial spaces, and the literal foundation of it all must be able to withstand the onslaught.

It can be designed with specific additives to give them special properties. So whether you’re in a workshop that needs anti-slip flooring or a laboratory where anti-static protection is key, this material can be the answer.

From manufacture to finishing Hawk CFC does it all. We’ve served Perth and the surrounds since 2014 and can get you started with your project today. Just call us on 0490 777 761 or request a fast and FREE quote online.

How versatile is commercial epoxy flooring?

Most applications focus on durability. By adding coatings of this resin over an existing concrete slab, businesses and industrial spaces can protect the floor from harmful chemicals, liquids, and impact.

But this floor does more than just make it easy to wipe up spills. This resin acts as a versatile base for a number of additives that customise the floor for different uses. Here are just a few of the most popular:

- Design: Adds metallic pigment or vinyl flake for a designer look great for showrooms, retail stores, restaurant or bar dining areas, schools, and office buildings.

- Anti-static: Contains conductive materials that dissipate any electrostatic charge to protect electronic equipment in laboratories, data centres, and telecom facilities.

- Vapor barrier: Creates an impervious surface that keeps vapour and moisture out of the floor in common spaces, rentals, and apartment complexes.

- UV protection: Blocks UV rays to preserve the look and colour of surfaces that receive natural light including outdoor spaces.

How long does it take to install this type of floor?

This is often a factor of the size of the space and the condition of the existing concrete floor. For example, fresh concrete with little to no staining, damage, or debris is fairly easy to prep. The surface can be easily cleaned and the process started the same day. However, if there are cracks to repair or oils to remove first, the project will take a bit longer. It also goes to say that the larger the space, the longer it will take to apply the actual coating itself.

Each coating must be allowed adequate time to cure before the next coating is applied. This can take between 12-18 hours. After all of the layers and top coat are done, the floor only takes 7 days to completely cure.

Does this type of floor come with a warranty?

Not even these floors are 100% indestructible. Most coating products are backed by a manufacturer limited warranty as long as they are applied correctly. This will protect against defects in the actual product lamination and concrete protection. It is always best to choose a professional installer that includes a warranty on their workmanship.

What to look for in an installer

This type of floor in particular requires a great deal of experience and skill to be done properly. That’s why it’s best to choose a professional concrete service that specialises in this type of application. When looking into providers, be sure to ask about their depth of experience and the variety of projects they have worked on. Don’t be afraid to ask about their portfolio or if there are locations you can visit that show off their work.

From there, you can also ask the following questions to be certain you are moving forward with an installer that can meet your needs:

- “Do you have customer references I can call who had a similar project to mine?”

- “How long will our project take to complete including all layers and cure time?”

- “What licenses and insurance can you show for your company and team?”

- “Do you manage all services internally or do you work with subcontractors?”

- “Do you provide concrete repair and prep services or are those charged separately?”

- “What options do you have for additional finishes or design elements?”

- “How long have you been in business in our area?”

- “What products or brands do you use in your commercial applications?”

Why Choose Hawk CFC

Commercial epoxy flooring can feel like a big project, but it’s also a major boon to any space. With a more durable, easy to clean, professional floor, businesses can focus on what they do best without sinking funds into repeated repairs or diminishing aesthetics.

Hawk CFC specialises in managing the entire process from manufacture to installation. All of our work is backed with a guarantee for materials and labour, so you can be confident you’re getting the best solution available in Perth. We offer consulting and innovative solutions to help commercial providers of all types install the floor that meets their design and durability needs.

We also pride ourselves on superb customer service, which starts with a no-obligation consultation. Call us on 0490 777 761 or tell us about your flooring project online to get started.

Frequently Asked Questions About Perth Commercial Epoxy Flooring

What commercial spaces are best for this type of floor?

At its core, this type of floor is an amazing solution for nearly every kind of commercial or industrial space. With the ability to add non-skid, design, anti-static, anti-microbial, and other additives, customers are able to find the right fit for their needs (while also matching any design, colour, or gloss requirements). This floor is popular in spaces including:

Do these floors require special maintenance?

Arguably the biggest benefit of these floors is that they require little to no maintenance. In high traffic, high use spaces across commercial industries, the last thing that facility operators want to worry about is their flooring.

Most floors will resist or withstand impact, spills, chemicals, and heat. With that said, effort should be made to remove anything corrosive or tinted promptly. Regular sweeping or mopping with water is almost always enough to wipe away debris. This can also help the coating last, since repeated grinding of dust or dirt underfoot can very slowly wear away protective layers.

How long will a commercial epoxy flooring system last in Perth?

Professionally installed floor is designed to last between 5-10 years. The variation here comes from the extent of use or how much the layers are worn over time. The great news here is that this material will do its job to protect the concrete substrate, and it is fairly straightforward to have an additional touch-up layer applied in areas of high use.

What are the most common issues?

Since these floors are low maintenance and durable, they are not prone to giving their owners many problems during use. The most common issues come from installations that are not properly completed. This is why it is so essential to call in experts. Otherwise, your floor could show signs of peeling, bubbles, cracking, moisture accumulation, or color fade.

Why Choose Us

West Australian Owned and Operated

Proudly Western Australian since 2014.

Guarantee

Ask us about our Delamination Warranty that covers both Materials used and Workmanship.

Custom Resins

Our Western Australian plant allows us to produce specific resins for our clients.

MANY Industries

We work with commercial sectors, the food industry, pharmaceutical, healthcare, mechanical and equipment workshops, etc.

Non-Slip

We tailor-make your floor to achieve the desired cleanability and slip resistance rating.

FREE Consultation

Choosing a floor can be challenging. We’re here to guide you along every step of the way with neutral advice on what floor is the right option for your business.

Safety First

Safety is at the core of our business values. Ask us how we can keep your team safe.

From Manufacturing To Installation

We are the only West Australian installation company with its own local manufacturing plant. We can handle the entire process from production to installation to save you money.

Flooring For LIFE

In 2014, we proposed to transform the food industry by removing the “grout & seams”. Specialising in HACCP Accredited Silikal© GmbH Reactive Resins, we are passionate about providing our customers with seamless, easy-to-use non-slip surfaces.

Our Trusted Suppliers

RRTS – Rapid Return To Service Flooring

We specialise in minimising your downtime. We have heavy equipment to prep fast and rapid cure resins which often allow for an immediate cure.

Comprehensive Solutions Through Distributorships

We are the West Australian distributor for Silikal GmbH and Alluvius, as well as many accreditations for alternate suppliers.

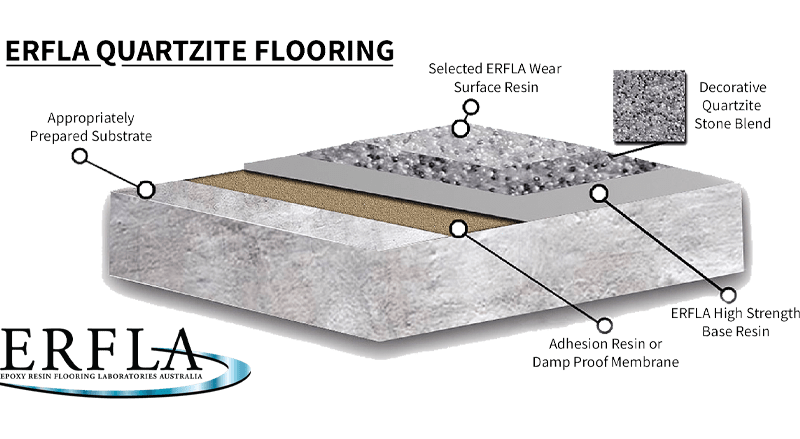

Multi-Layered Specialty Systems

Allow us to specify a system that takes into account your unique environment and goals.

CM3

We’re happy to show our health and safety capabilities.

Zero VOC Flooring

We offer beautiful, non-toxic, eco-friendly floors.

Our Certifications

In food safety management, a fundamental approach to managing risk is implementing a HACCP system.

This acronym stands for Hazard Analysis and Critical Control Point.

The development of a HACCP plan must identify and manage the following types of hazards: Biological, Chemical, Physical, Allergens, Quality, and Regulatory.

Our Work

What Our Clients Are Saying..

Thanks to the Hawk CFC Team for your contribution to our company- great knowledge, and attention to detail, and a professional team.

Rhett is one of the best trade business owners I have met. Our renovation had complications, but he and his guys have worked tirelessly to achieve a unique and awesome floor. I’ve had some great trades on our recent renovation and Rhett has stood out as honest and passionate about what he does.

Hawk Concrete Floor Coatings did an outstanding job with the high pressure clean and sealing of our driveway, garage & paving! Team were friendly & professional. We are actually getting more paving done with our landscaping, will need them back to seal the new paving too. Highly recommend Hawk for your next job residential or commercial.

These guys did an amazing job on our kitchen floor and dining floor in our Fremantle cafe. Everyone is impressed and the health department loves it. Couldn’t recommend them more highly. Thanks guys.

They are an amazing bunch of people. Really high standards set and maintained in all aspects of the job.

Connected with Hawk Concrete Floor Coatings through hipages.com.au and we have confirmed that they would recommend them.